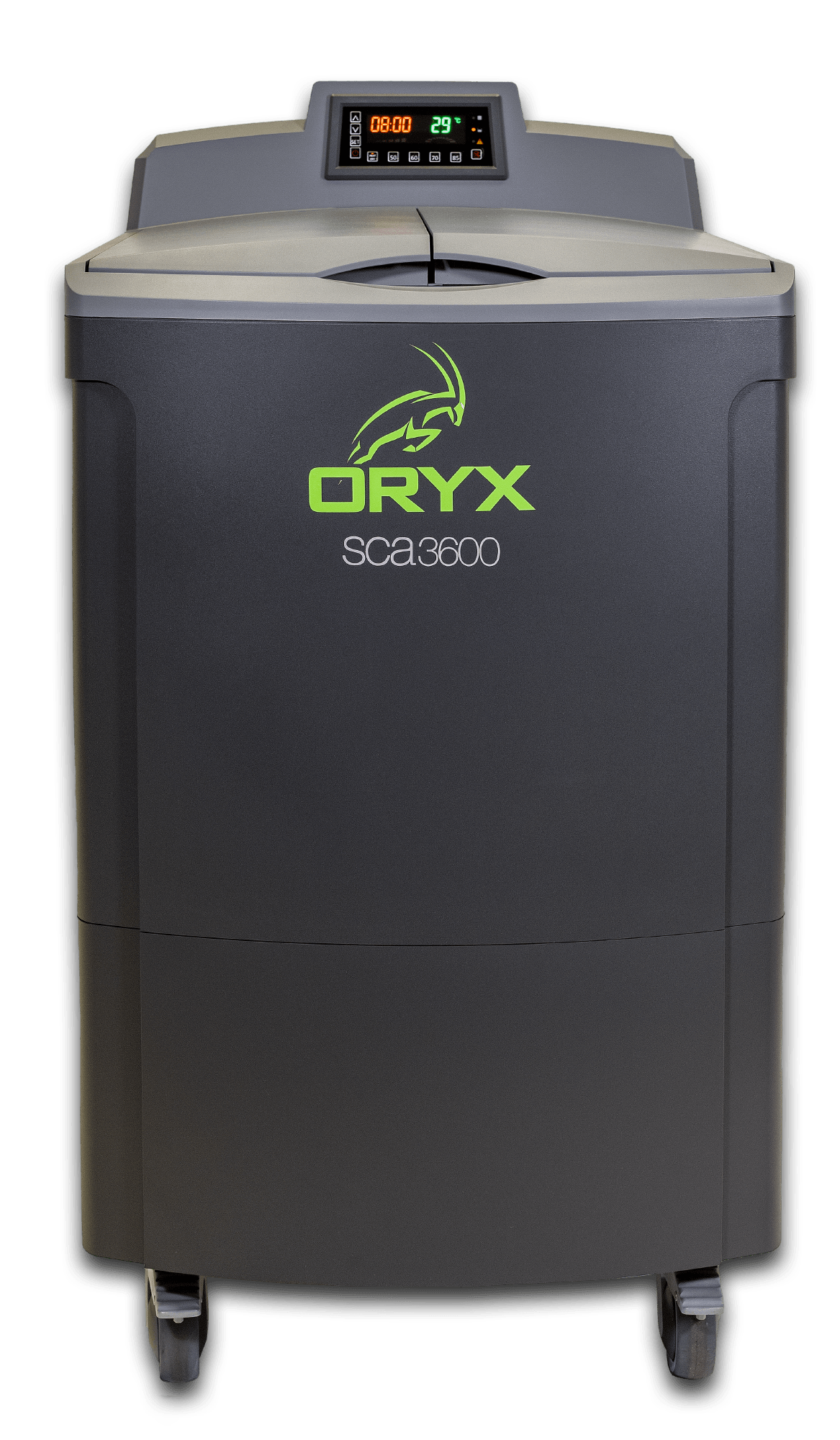

sca3600

Optimized Performance with More Capability and Capacity

sca3600

Designed for User Productivity and Comfort, Engineered for Function and Quality.

The sca3600 is a large industrial & high throughput solution for removal of soluble support materials on 3D printed parts. It provides demonstrated options to perform support removal on multiple materials such as ABS, ASA, PC, Nylon, PEEK, etc. In removing support for FDM/FFF and Mate- rial Jetting processes, such as Polyjet or Extrusion Technology, the sca product family provides a wide range of predefined machine settings and is fully compatible with all soluble support material concentrates, from water to caustics. It further provides the user with the appropriate level of agitation to balance the needs of heavy removal while maintaining critical dimensions on delicate or intricate part geometry. With additional features that include a simple electronic interface for pre-set temperature & time, easy part loading & unloading, and durable stainless-steel tank for caustic support removal operations, the sca3600 is your finishing solution!

sca3600

Designed for User Productivity and Comfort, Engineered for Function and Quality

- Overall Size: 36.5L x 22.8 W x 42.8 H in. (92.7 L x 57.9 W x 108.7 H cm)

- 16 x 16 x 14 in. (40.6 x 40.6 x 35.6 cm) Stainless Steel Removable Parts Basket

- Capacity: 27 gallons (102 liters)

- Power Requirements: 230VAC +/- 10%, ~ 50/60 Hz - 15A - 3400W

- 4 x 4 x 4 in. (10 x 10 x 10 cm) Small Parts Basket included

- Stainless Steel Tank & Durable Pumping System compatible with water-soluble and caustic-soluble printed support materials

- Proven Support Removal from FFF/FDM parts including ABS, ASA, PC, Nylon, PEEK, and others

- Presets designed for 3D printed parts temperatures: 50°, 60°, 70° and 85° C

- “Heat Off” temp. selection for Material Jetting & Curing (MJ), such as Polyjet

- User-controlled Digital Timer

- Unique Spray Nozzle & Pump Configuration provides optimized & patented flow

- Flow Reducer is included for delicate parts

- Whisper-quiet Operation for in-office use or industrial setting

- Integral Hinged Lid to reduce water waste & maintain accurate temperature

- Built-in Safety Features such as Over Temperature & Water Level Alarms

- Field replaceable Sub-assemblies

- CE/ cTUVus/ RoHS/ WEEE/ RCM Regulatory Approvals

- 1 Year Warranty & US-based Technical/Customer Support with strong AM industry experience

sca3600 User Manuals

Click below to download user manuals and product spec documents for the sca3600.

The sca3600 provides a larger system capacity with a range of cleaning options and accessory components. Its reliable, easy- to-use, and quiet operation makes it a superior product for AM service firms and industrial manufacturers, where producing larger intricate parts and/or high throughput is necessary. Manufactured for long-term reliability in highly caustic industrial environments while providing limited maintenance and simple servicing, sca3600 by ORYX is the benchmark standard for large part/high volume soluble support removal.

FAQ

Support

Register

Call us Today to Learn More