MakerBot Partners with Oryx Additive to Offer Support Removal Solutions to Customers

BROOKLYN, NY, December 15, 2020 – MakerBot, a global leader in 3D printing and subsidiary of Stratasys Ltd. (Nasdaq: SSYS), has partnered with Oryx Additive to provide additive manufacturing support removal and finishing solutions to METHOD customers.

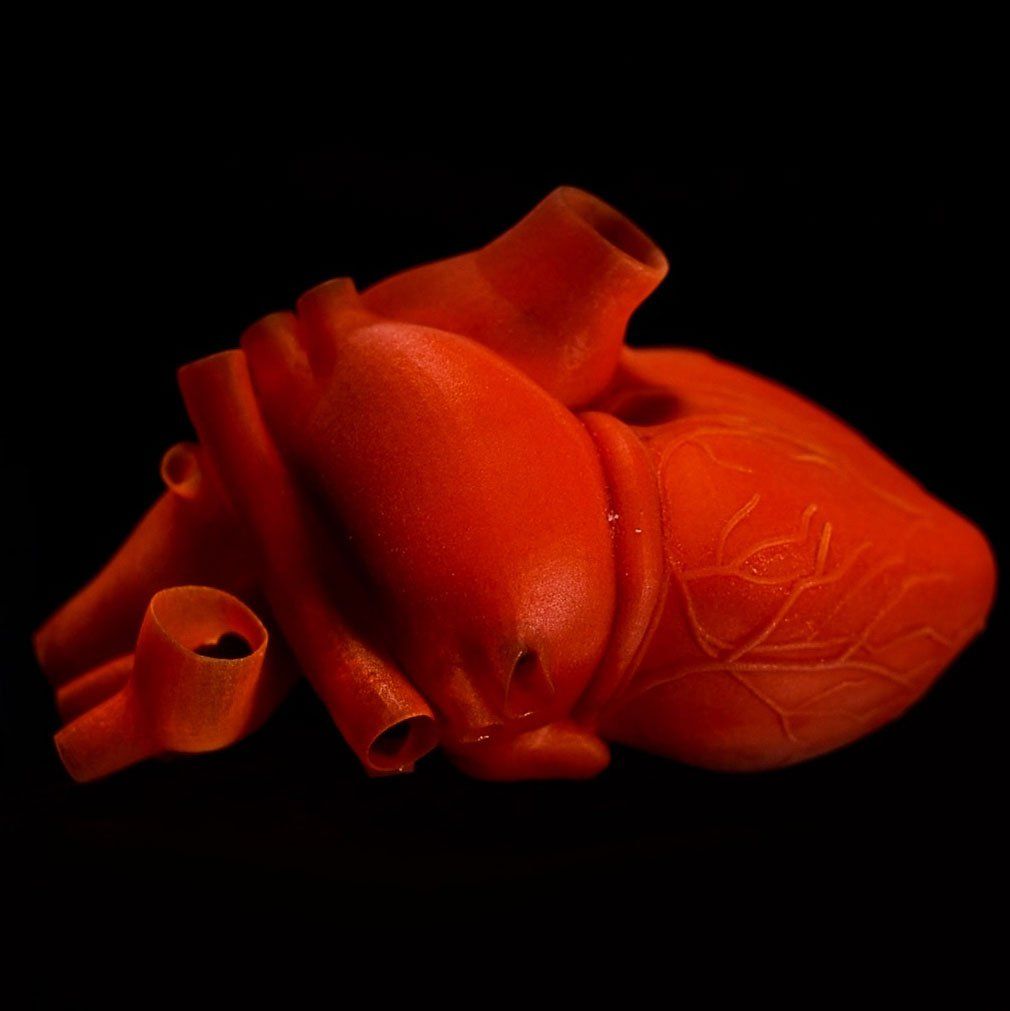

The Oryx Additive sca1200ht wash tank is specifically designed for the removal of soluble support materials on 3D printed parts. The sca1200ht is compatible with all solvent-based and water-soluble support materials as well as base modeling materials in conjunction with all recommended support removal concentrates. Model materials include ABS, ASA, Nylon, and polycarbonate materials.

METHOD’s industrial features are designed to enable the printer to deliver industrial reliability and precision in order to achieve consistent and repeatable prints that match design dimensions. With its up to 110°C heated chamber, METHOD can be used to print advanced materials and explore new applications. Combined with soluble supports, such as MakerBot PVA and Stratasys® SR-30, METHOD enables users to print with unlimited design freedom and part complexity.

“Our vision at Oryx is to achieve the full potential of additive manufacturing by collaborating with customers and being a trusted partner. With METHOD, MakerBot has forged a new path towards industrial 3D printing. METHOD’s industrial capabilities and advanced materials enable it to print a range of applications nearly on par with its traditional counterparts. With the sca1200ht, METHOD users can take their post-processing and support removal to a level commensurate with the reliability expected at the industrial level. We are ecstatic to partner with a great company, with great products, led by great people!,” said Keith Jeffcoat, Chief Executive Officer, Oryx Additive.

Oryx Additive specializes in the design, development, and manufacturing of finishing and post processingequipment for additive manufacturing. Their SCA product line includes the popular sca1200ht as well as the sca3600. The company distributes its products across multiple sub-catagories of the additive manufacturing industry, including consumer products, design and engineering, automotive, aerospace, and additive manufacturing.

“METHOD was designed as an industrial platform with the ability to allow users to experiment with new and different advanced engineering materials. Combined with soluble supports like PVA or SR-30, users can print parts with complex geometries, like internal cavities or overhangs. We are thrilled to work with Oryx to offer one of the most popular and efficient cleaning solutions on the market,” said Johan-Till Broer, Vice President of Product Development, MakerBot.

The MakerBot METHOD wash tank is currently available and can be purchased online or through MakerBot resellers.

About MakerBot

MakerBot, a Stratasys company, is a global leader in the 3D printing industry. The company helps create the innovators of today and the businesses and learning institutions of the future. Founded in 2009 in Brooklyn, NY, MakerBot strives to redefine the standards for 3D printing for reliability, accessibility, precision, and ease-of-use. Through this dedication, MakerBot has one of the largest install bases in the industry and also runs Thingiverse, the largest 3D printing community in the world.

We believe there's an innovator in everyone, so we make the 3D printing tools that make your ideas matter. Discover innovation with MakerBot 3D printing.

To learn more about MakerBot, visit makerbot.com, the MakerBot blog, Twitter, LinkedIn, or Facebook. Stratasys (parent company of MakerBot) reserves the right to utilize any of the foregoing social media platforms, including the company's websites, to share material, non-public information pursuant to the SEC's Regulation FD. To the extent necessary and mandated by applicable law, Stratasys will also include such information in its public disclosure filings.

MakerBot, MakerBot LABS, MakerBot METHOD, and MakerBot METHOD X are trademarks or registered marks of MakerBot Industries, LLC. All other trademarks are the property of their respective owners.

Note Regarding Forward-Looking Statement

The statements in this press release relating to Stratasys’ and/or MakerBot's beliefs regarding the benefits consumers will experience from using the MakerBot METHOD wash tank are forward-looking statements reflecting management's current expectations and beliefs. These forward-looking statements are based on current information that is, by its nature, subject to rapid and even abrupt change. Due to risks and uncertainties associated with Stratasys' business, actual results could differ materially from those projected or implied by these forward-looking statements. These risks and uncertainties include, but are not limited to: the degree of our success at introducing new or improved products and solutions that gain market share; the degree of growth of the 3D printing market generally; the duration of the global COVID-19 pandemic, which, if extensive, may continue to impact, in a material adverse manner, our operations, financial position and cash flows, and those of our customers and suppliers; the impact of potential shifts in the prices or margins of the products that we sell or services that we provide, including due to a shift towards lower-margin products or services; the impact of competition and new technologies; potential further charges against earnings that we could be required to take due to impairment of additional goodwill or other intangible assets; to the extent of our success at successfully consummating acquisitions or investments in new businesses, technologies, products or services; potential changes in our management and board of directors; global market, political and economic conditions, and in the countries in which we operate in particular (including risks related to the impact of coronavirus on our operations, supply chain, liquidity, cash flow and customer orders; costs and potential liability relating to litigation and regulatory proceedings; risks related to infringement of our intellectual property rights by others or infringement of others' intellectual property rights by us; the extent of our success at maintaining our liquidity and financing our operations and capital needs; the impact of tax regulations on our results of operations and financial condition; and other risk factors set forth under the caption “Risk Factors” in Stratasys’ most recent Annual Report on Form 20-F, filed with the Securities and Exchange Commission (SEC) on February 26th, 2020. Readers are urged to carefully review and consider the various disclosures made throughout our 2019 Annual Report and the Report of Foreign Private Issuer on Form 6-K that attaches Stratasys’ unaudited, condensed consolidated financial statements and its review of its results of operations and financial condition, for the quarterly period ended March 31, 2020, which we furnished to the SEC on May 14, 2020, and our other reports filed with or furnished to the SEC, which are designed to advise interested parties of the risks and factors that may affect our business, financial condition, results of operations and prospects. Any guidance provided, and other forward-looking statements made, in this press release are made as of the date hereof, and Stratasys and MakerBot undertake no obligation to publicly update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as required by law.