Oryx Additive Launches scaWaterjet

Setting the NEW standard for water jet spray technology – in the finishing of 3D Printed Parts. Done with Productivity & Comfort all within a Superior product.

TEMPE, AZ, APRIL 2, 2021 – Oryx Additive to provide a more ergonomically considered solution to help industry manufacturing scale up their support removal efficiencies and improve other finishing processes.

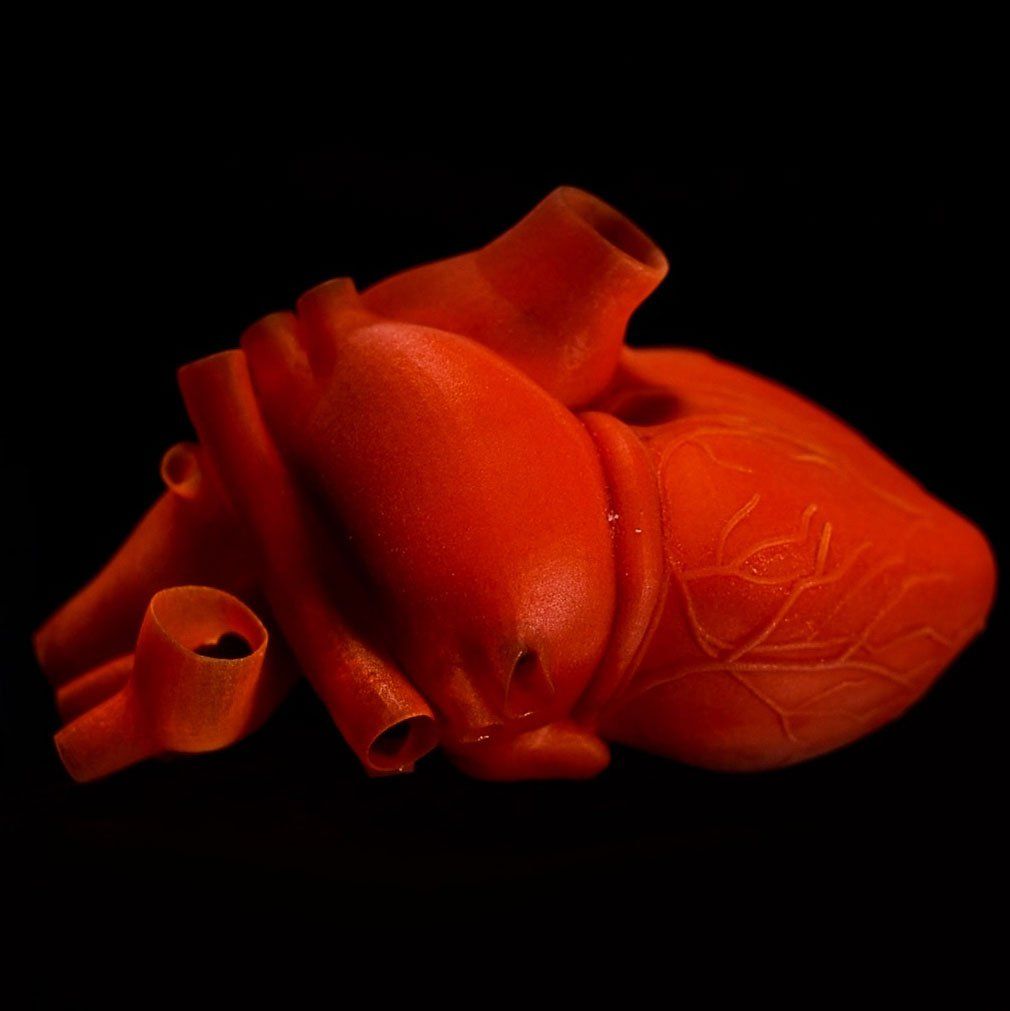

The Oryx Additive scaWaterjet* is specifically Designed for user productivity and comfort - Engineered for function and quality. This water-pressure cleaning station is capable of removing support material from multiple 3D printed models rapidly, with bulk and/or fine detail jetting options. The ergonomic, aesthetically considered and “patent pending design” provides operators with sit or stand option. The cleaning of additive parts may be delicate or rigid, and accomplished in minutes vs. hours. Some of the amazing features include large tilted clear-view operation, LED-illuminated work area, dual filtration, easy access to pump & holding tank, and direct plumbed water source or stand alone “recycle tank” operations (great for industrial / office locations where water plumbing may not be accessible). Many more features are viewable on the Oryx product webpage.

“Our vision at Oryx is to achieve the full potential of additive manufacturing by collaborating with customers and being a trusted and responsive partner. With the scaWaterjet, all users may expedite their finishing and support removal with the reliability expected at the industrial level. “We are excited to launch this new and innovative product” said Keith Jeffcoat, Chief Executive Officer, Oryx Additive.

Oryx Additive specializes in the design, development, and manufacturing of finishing and secondary processing equipment for additive manufacturing. Oryx builds with a heavy focus on reliability and durability that the additive manufacturing industry demands. Their SCA product line includes the new scaWaterjet, the tried-and-true sca1200ht as well as the sca3600. The company distributes its products across multiple sub-categories of the additive manufacturing industry, including consumer products, design and engineering, automotive, aerospace, medical, and various additive manufacturing verticals.

The Oryx systems are currently available and may be purchased online at www.oryxadditive.com or through our reseller network. Feel free to contact us to explore how we may assist in providing additional information or product testing for your unique needs and applications.

*scaWaterjet is proudly designed (patent pending) and developed by Oryx in Tempe, AZ USA

About Oryx Additive

ORYX Additive was founded and spun off from a 25-year-old successful engineering and design-based company (PADT). The goal was to assist additive manufacturers increase output, while improving upon quality levels. This was done by developing and implementing proven, controlled, and integrated finishing technologies and processes, tailored to their unique needs. We innovate to design, develop and refine the tools, all techniques and equipment that will further enable the future of additive manufacturing.

Our Vision… Collaborate with our customers to achieve the full potential of additive manufacturing. Our Mission… Be the trusted partner in the development of comprehensive solutions to meet the needs of our customers.