Oryx Additive Provides Trusted Solutions To STEM-Based Programs

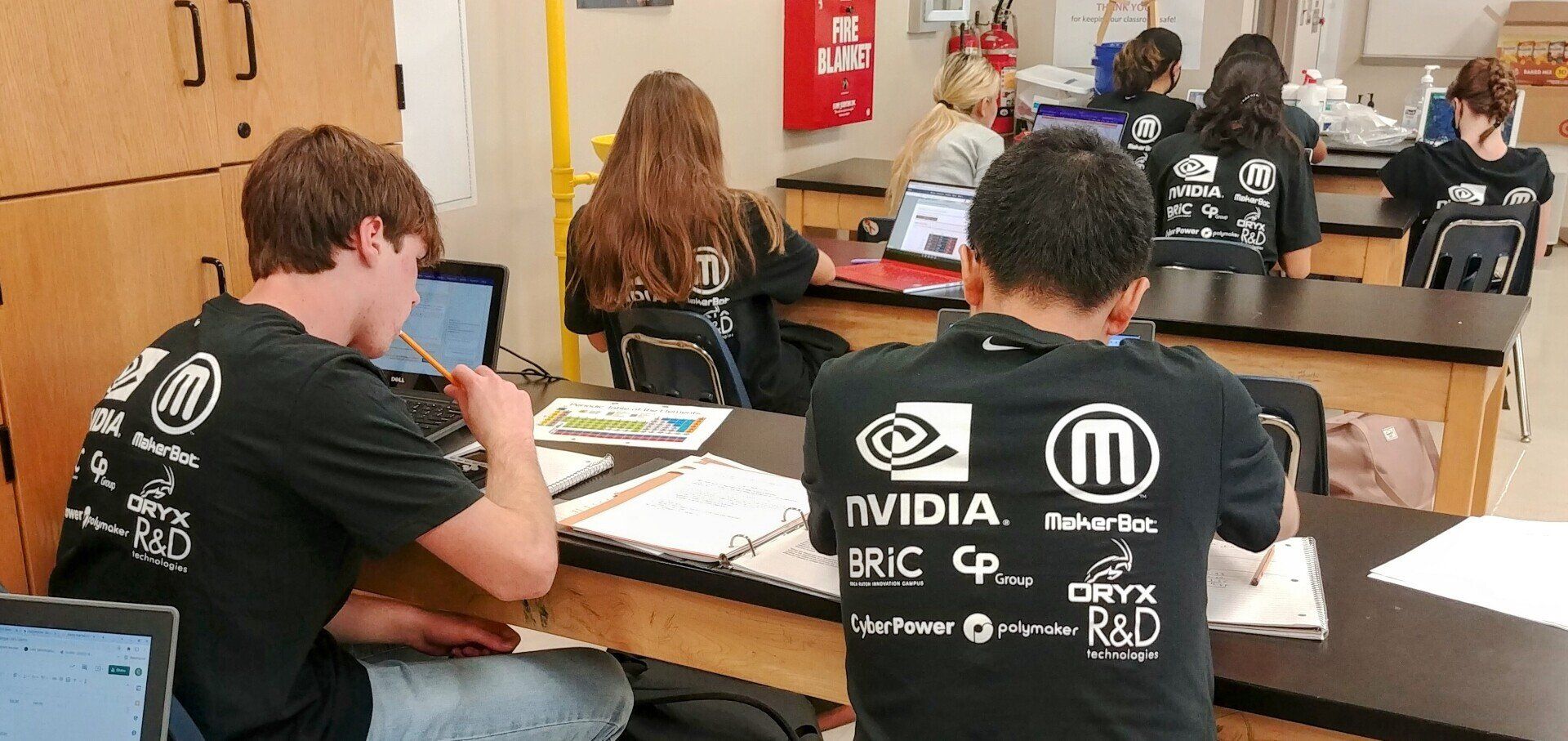

Oryx Additive partners with Boca Raton Community High School, providing trusted finishing solutions that help to further the knowledge and passions of the students within the Science Olympiad Team. The Science Olympiad is one of the nation's largest STEM competitions featuring 23 events that span all areas of science including biology, chemistry, physics, forensic science, and engineering.

Boca’s program has been around for fourteen years, winning 12 Regional Championships, 8 State Championships, and placing as high as 12th in the nation, overall. The students of BRCHS have won multiple National Champions in individual events as well, priding themselves in their ability to push the limits of what is possible in a High School classroom.

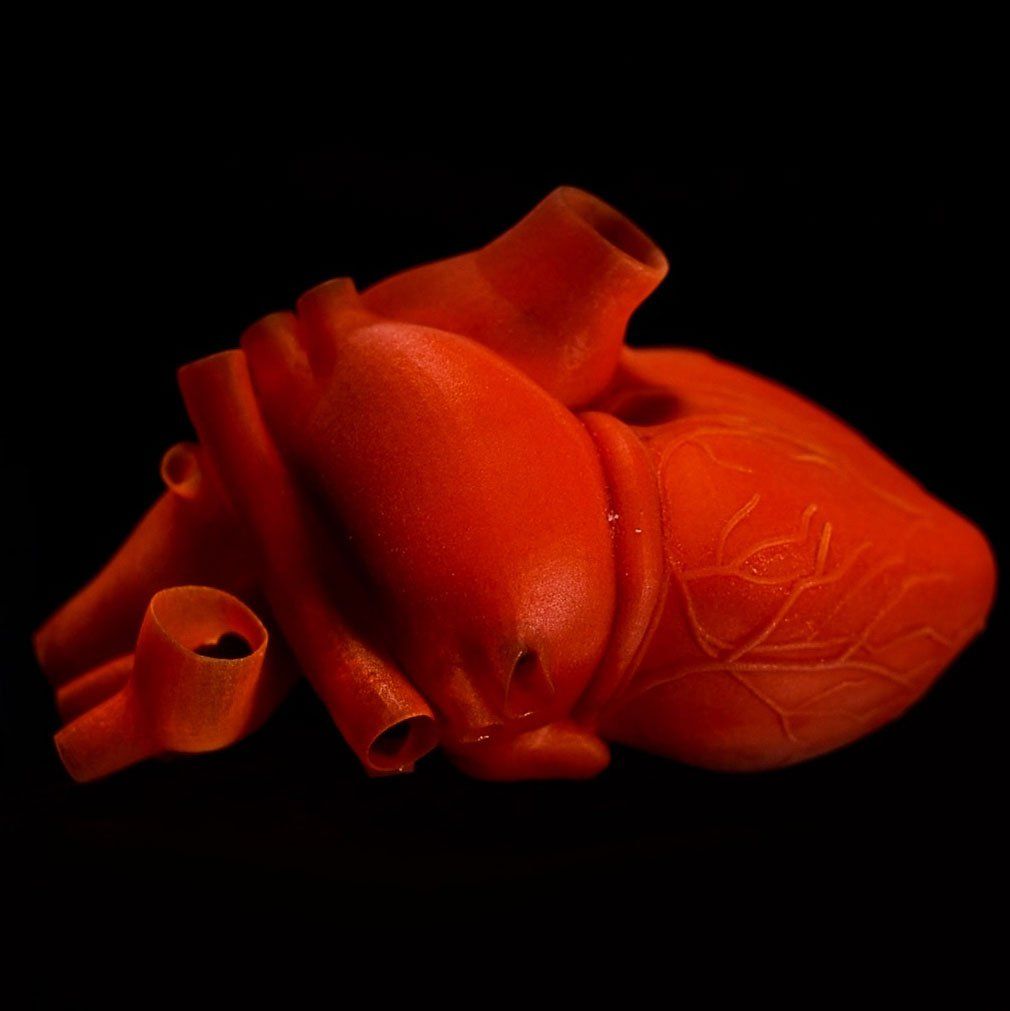

Some of the events in the Science Olympiad include "study" events in which students complete exams, others are "lab" events where students are completing a lab and an exam, and the remaining are "build" events that require pre-built devices to accomplish a specific task. Students work all year to study and build based on a specific set of rules that change on a yearly basis. For Boca’s builds, they primarily focus on iterative prototyping. Nearly all of the student builders are trained to 3D print on the Makerbot platform.

Currently, the school utilizes four Makerbots (1 Method X, 1 Z18, 2 Replicator +). Students usually begin the design process on the whiteboard or paper, brainstorm, then design in Autocad Inventor. From there, the students print prototypes out of PLA on the Rep + machines. Once the students have found a prototype that they like, the Method X is used to print the designs out of better composites, such as nylon carbon fiber. This is where Oryx Additive and our proven Support Cleaning Apparatus (sca) product family come in to help. Many of the pieces that are designed have internal structures that require through holes, overhangs, and complex geometries. By using Oryx Additive's patented sca products, students are able to effectively finish parts without jeopardizing the quality of 3D prints.

“The Oryx submersion tank (sca1200ht) has been an essential tool that has enabled students to 3D print without restrictions on internal structures and supports. With a simple wash, these supports dissolve which leaves a high-quality object. The tank has enabled students to print designs not previously possible.” Mr. Jon Benskin, Science Olympiad Head Coach

By removing the limitations of internal structures and supports, students can focus on pushing the limits of 3d printing to a level not previously achievable until now.

Oryx is honored to be part of Boca Raton’s journey enabling the students/team to achieve their full potential. Congratulations to the Science Olympiad team for their outstanding performance and success. The team at Oryx wishes all the best in the team's qualification for Nationals!